How do you iterate on a robotic design?

An RAF Leeming Airman interacts with a new Boston Dynamics Spot robot during Agile Liberty.

Multi-Domain Complexity and Simulation

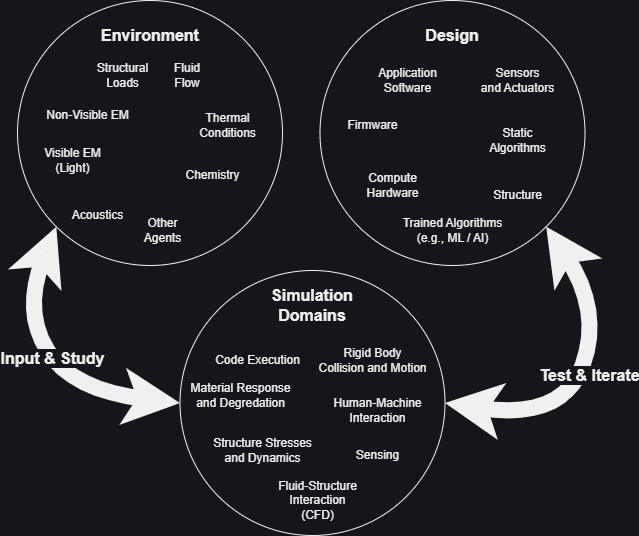

A single design iteration represents a unique configuration of hardware like sensors, actuators, and structural components, software like control algorithms, trained neural networks, and pathfinding algorithms, and firmware like drivers and networking stacks. All of these components may interact with one another and the environment in surprising ways. State of the art products are looking more and more like robots, yet simulation and test tools are typically domain-specific and don’t support software-in-the-loop. The alternative to simulation is real-world testing which is painfully slow and expensive.

Modern products require tightly coupled simulation across many domains including software.

State of the Art Digital Twin Tools

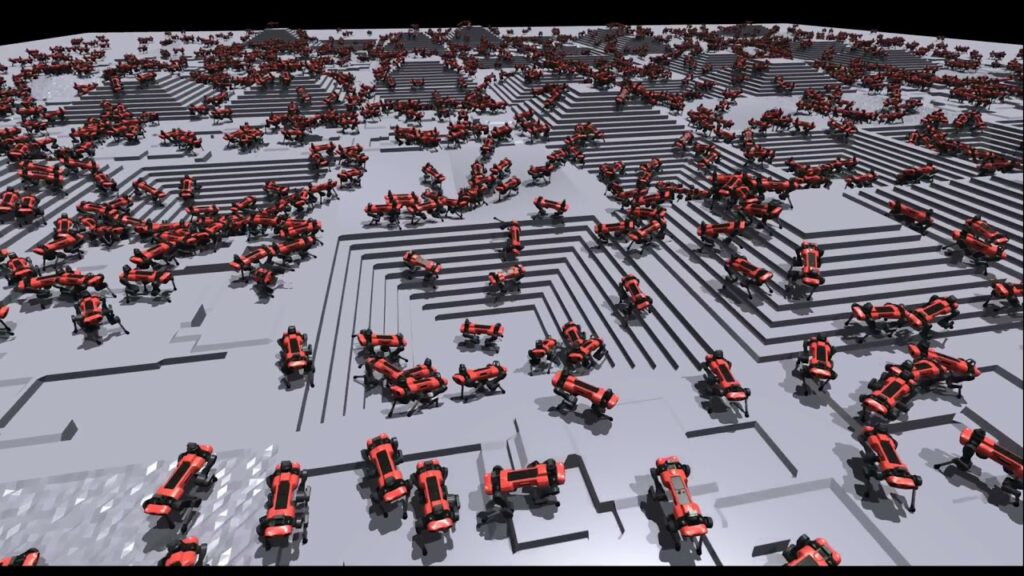

NVIDIA recognized the opportunity in this space and developed Omniverse. Omniverse aims to be a unified platform for developing multi-domain digital twins from architectural design models to finite element flow models to complete robotic simulations. Isaac Lab in particular parallelizes the environment-in-the-loop training of machine learning algorithms for robotics applications by running hundreds of robots at once in a shared simulated environment.

Hundreds of dog robots learn to walk simultaneously in Isaac Gym.

3D development tools like Unity, Unreal, Blender are also dipping their toes in this market, and players that were once confined to the robotics space like Gazebo are expanding their capabilities to integrate or compete with digital twin creation tools.

Systematic on the Digital Twin Frontier

Systematic develops high quality products requiring careful multi-disciplinary design. Recently, Systematic Consulting Group has saved weeks of effort and explored much more of our design space by using digital twins in Blender to inform physical prototypes of sophisticated computer vision hardware for sports applications. We have also used digital twins in NVIDIA Omniverse to explore the feasibility of tracking missiles with visible-light cameras. We’ll dive into how we did this, and survey the state of the art of digital twin tools in the coming weeks. Stay tuned!