AI That Actually Moves

the Needle

We don’t just experiment with AI—we engineer real-world applications that drive ROI. Our cross-disciplinary teams bring together data scientists, embedded engineers, and software architects to create tailored AI strategies that deliver measurable impact. Whether you’re enhancing an existing product or exploring new automation opportunities, we’ll help you harness AI in a way that aligns with your goals and infrastructure.

AI and Machine Learning Clients and Partners

What We Build with AI

Our team has deployed AI across a wide range of industries to enhance functionality, improve performance, and enable intelligent decision-making—whether it's on-device or in the cloud.

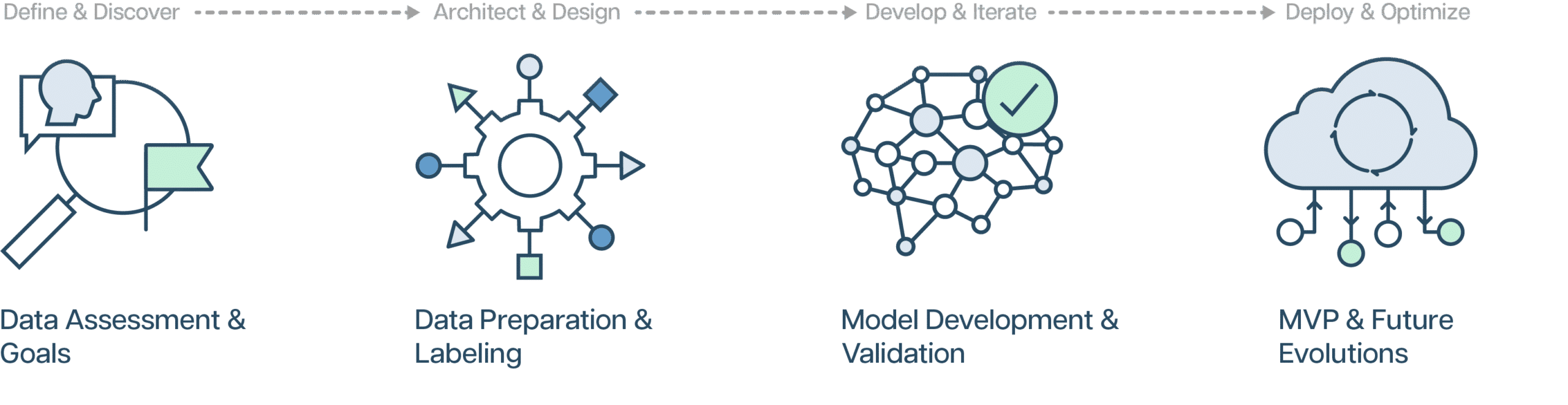

From Data to Deployment: A Full-Cycle AI Pipeline

We take a systematic, tech-agnostic approach to applying AI—ensuring each phase of the process is tightly integrated with your broader product development goals.

AI & ML FAQs

Stages of Product Development Lifecycle

There are various stages in our hardware design process that ensure sophisticated and efficient product quality.